Brake Hose: Flexible Pipe for Brake Fluid Transmission

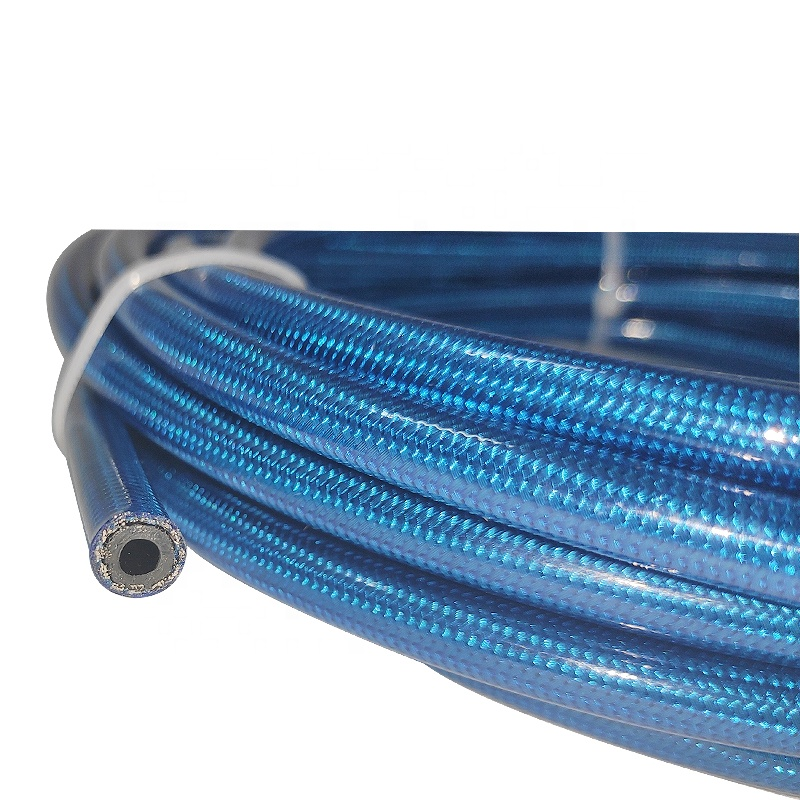

Brake hose generally refers to the flexible pipe in the vehicle brake system used to transmit brake fluid. It is usually made of materials such as rubber or plastic, and may have a braided layer or a metal mesh on the outside for reinforcement to enhance its pressure resistance and tensile strength. Types of brake hoses include steel braided brake hose, which has high strength and wear resistance; stainless steel brake hose with good corrosion resistance; PTFE braided hose with excellent chemical resistance and high temperature resistance; motorcycles brake hose designed specifically for motorcycle brake systems; nylon brake hose made of nylon with good wear resistance and oil resistance; and PTFE brake hose made of PTFE maintaining stable performance under high temperature and pressure. These different types of brake hoses meet various needs of different brake systems.

Get A Quote