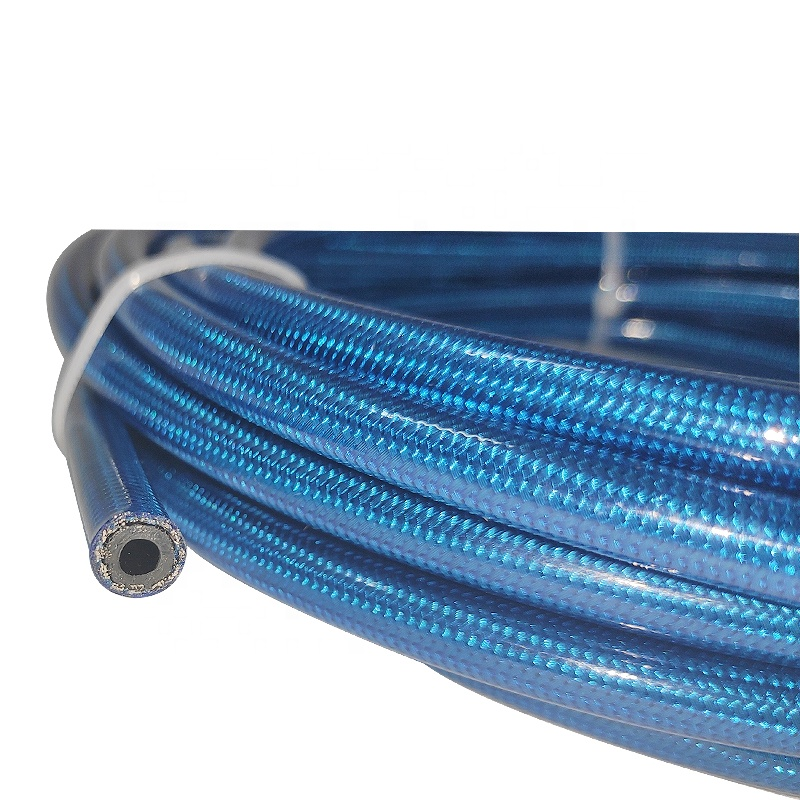

High Flexibility for Complex Installations

Brake hoses are extremely flexible. They can be bent and shaped to fit complex installation spaces in vehicles, such as around wheels and in tight engine compartments. This flexibility ensures proper connection of the brake system, adapting to different vehicle designs.