Understanding the Role of Brake Hoses in Vehicle Safety

The Critical Function of Brake Hose in Hydraulic Braking Systems

The brake hoses are essentially what carries pressure throughout the hydraulic braking system, sending it from the master cylinder down to those calipers where the action happens. Pressing on the brake pedal sends hydraulic fluid rushing through these reinforced rubber or steel lines under serious pressure sometimes over 1,500 PSI according to SAE standards. This forces the brake pads onto the rotors which creates friction and turns all that motion energy into heat. If any part of this hose system gets damaged or worn out, studies show braking power drops between 18 to 32 percent as reported by Ponemon in 2023. That kind of reduction means longer stopping distances and real safety risks for drivers on the road.

Safety Implications of Failed Brake Hoses and Real-World Case Studies

Worn out brake hoses often lead to serious brake problems that can be dangerous on the road. Looking at accident reports from last year covering around 1,200 commercial vehicles, nearly half had issues with their brake lines either cracking or swelling and leaking brake fluid. There was even a real world example where a motorcyclist experienced a sudden rupture in his rubber hose while trying to stop quickly. This caused a noticeable delay in brake pressure response time, adding roughly 22 feet to the stopping distance when traveling at about 60 miles per hour. According to what mechanics see in workshops, brake hoses that follow the SAE J1401 specifications tend to hold up much better over time compared to cheaper options that don't meet these standards. The difference in reliability is pretty significant too.

SAE J1401 Standard for Hydraulic Brake Hoses and Compliance Benchmarks

The SAE J1401 standard establishes rigorous testing protocols for brake hose durability:

| Compliance Aspect | Test Method | Threshold |

|---|---|---|

| Burst Strength | Hydraulic pressure spike | 4,000 PSI |

| Temperature Resistance | -40°F to 257°F cycling | No cracks or deformities |

| Flexibility | 100,000+ bend cycles | 5% expansion |

Manufacturers must also conduct ozone resistance and cold bend tests to ensure performance under 15+ years of environmental stress. Third-party validation through certified labs remains essential for OEM and aftermarket compliance.

Rubber vs. Braided Stainless Steel Brake Hoses: Performance and Use Cases

Standard Rubber Brake Hoses: Durability, Cost, and OEM Applications

Most cars come with EPDM rubber hoses right from the factory, and about eight out of ten passenger vehicles use this type because they bend easily and don't break the bank. These hoses pass the SAE J1401 standards which means they can handle bursts up to around 2500 psi and work well even when temperatures drop below freezing or climb past boiling point. Normally these hoses last between six and eight years before needing replacement, but things get tricky in areas where road salt is common or there's lots of sun exposure. Studies show that under such conditions, EPDM degrades roughly 27 percent faster than those fancy braided options many mechanics recommend for harsh environments.

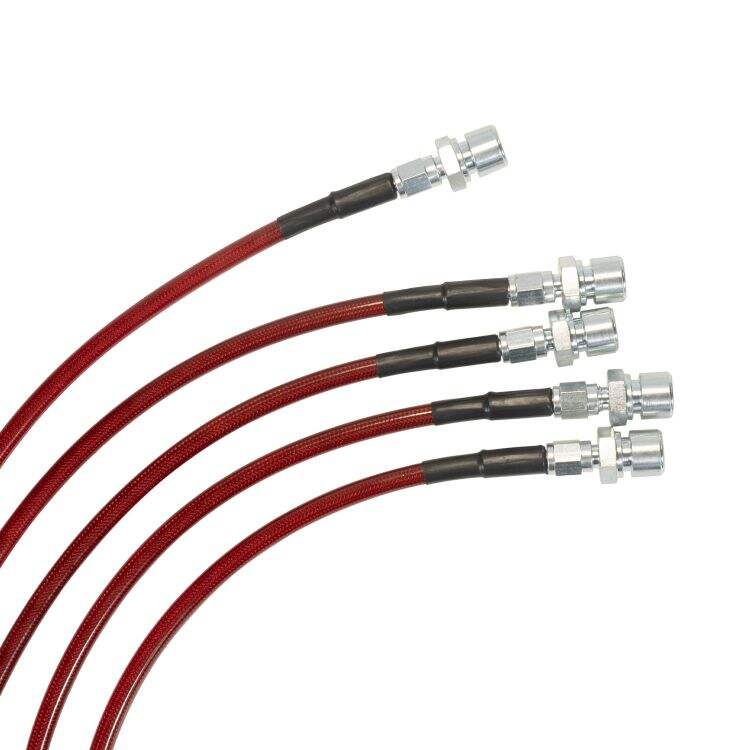

Braided Stainless Steel Brake Hoses: Performance Advantages and Motorcycle Use

Stainless steel braided hoses feature a PTFE inner core wrapped in aerospace-grade 304 stainless mesh, reducing volumetric expansion by 15% under high pressure. Key benefits include:

- 38% higher tensile strength than OEM rubber (3,800 psi vs. 2,750 psi)

- Minimal deflection (0.02 mm) during extreme motorcycle lean angles

- 62% longer lifespan in high-vibration environments like off-road trucks

These attributes make braided hoses the preferred choice for 92% of performance motorcycles and 74% of motorsport vehicles according to 2024 Hydraulic Component Trends.

Performance Differences Under High-Pressure Conditions

During panic braking (1,200–1,500 psi), braided hoses expand only 0.5% in diameter versus 3.2% for rubber (SAE J2494-2). This results in measurable improvements:

| Metric | Rubber Hose | Braided Hose |

|---|---|---|

| Pedal Travel Increase | 12–15 mm | 3–5 mm |

| Pressure Loss | 8–10% | 1.5–2% |

| Response Delay | 0.2 sec | 0.05 sec |

Are Aftermarket Braided Hoses Safer Than OEM Rubber? Debunking the Myth

The National Highway Traffic Safety Administration (NHTSA 2019) found no significant safety difference between well-maintained OEM rubber (failure rate: 0.0032%) and DOT-compliant braided hoses (failure rate: 0.0029%). While braided hoses excel in extreme conditions, improper installation—such as incorrect banjo bolt torque—accounts for 41% of failures (AutoCare Association 2022).

Key Specifications for Selecting the Right Brake Hose

Brake Fluid Compatibility and Hose Material Requirements

Material compatibility with brake fluid is critical. EPDM rubber works with DOT 3 and DOT 4 glycol-based fluids, while silicone-based DOT 5 requires PTFE-lined hoses to prevent swelling. The SAE J1401 standard mandates immersion testing in brake fluid at 212°F for 120 hours, allowing no more than 40% loss in tensile strength (FMVSS 106).

| Material | Compatible Fluids | Max Temp Resistance | Burst Strength Threshold |

|---|---|---|---|

| EPDM Rubber | DOT 3, DOT 4 | 250°F | 3,000 psi |

| PTFE-Lined | DOT 5 | 300°F | 4,500 psi |

Performance Specs: Burst Strength, Tensile Strength, and Volumetric Expansion

All brake hoses must exceed FMVSS 106’s minimum burst strength of 4,000 psi, with high-performance variants reaching 6,000 psi. Volumetric expansion is limited to 4.5 mL/m at 1,450 psi under SAE J1401 to avoid spongy pedal feel. For performance applications, tensile strength above 2,500 lbf ensures structural integrity during aggressive braking.

Inner and Outer Diameter Tolerances and Their Impact on Flow Efficiency

Precision tolerances (±0.010") prevent flow restrictions that increase pedal effort by 15–20%. Oversized inner diameters (3/16") reduce fluid velocity and delay caliper response, while undersized hoses amplify pressure spikes. OEM systems require flow rates of 0.5–1.2 gallons per minute, achievable only when adhering to SAE J2494 diameter guidelines.

Flexibility and Movement Accommodation in Dynamic Brake Systems

Optimal hoses bend 180° repeatedly without kinking—a necessity for motorcycles with over 5.9" of suspension travel. The SAE J1401 cold bend test subjects hoses to -40°F for 72 hours, requiring 10% increase in bending force. Poor routing with less than 1.25" clearance from moving parts causes 23% of premature failures (NHTSA 2022).

Vehicle-Specific Compatibility: Matching Make, Model, and ABS Requirements

Understanding OEM Engineering Tolerances and Factory Specifications

Manufacturers design brake hoses to exact hydraulic, thermal, and spatial specifications. A 2024 study found that 92% of brake failures in modified vehicles stemmed from incompatible hose lengths or fittings. Proper clearance with suspension and ABS components is crucial—deviations as small as 2 mm can lead to accelerated wear.

Ensuring Compatibility with Make, Model, Year, and ABS Integration

ABS systems these days really need tight control on how much they expand when pressurized (less than quarter of a percent at around 2900 psi) so they can modulate pressure accurately. Take the BMW R1250 GS as an example it needs those three layer PTFE hoses because of all the vibrations from riding rough terrain. Heavy duty trucks are different story altogether though, most mechanics will tell you steel braided reinforcement is practically mandatory for them. Anyone thinking about moving up to an ABS system that works with ADAS should check if it meets SAE J2494-2 standards first thing. That's what makes sure everything plays nice together with the electronic stability control features.

Application Across Cars, Motorcycles, Trucks, and Trailers

Most passenger cars run on 3/16 inch hoses that can handle around 1800 psi pressure, but performance motorcycles require thicker quarter inch lines capable of withstanding well over 3000 psi. Trailers present their own set of problems too. According to Airstream's data, nearly 4 out of every 10 brake issues in towed vehicles come from rubber hoses that have broken down due to road salt corrosion and constant UV exposure from being outside. Don't just assume one size fits all when it comes to these components. The specs really do vary across different makes and models. Take the Ford F-150 for instance which has model specific anti lock braking systems, versus something like the Honda Gold Wing where the front and rear brakes are electronically linked together in a completely different way. Always check what the factory recommends for each particular application.

Key Compliance Checks

| Vehicle Type | Minimum Burst Pressure | Temperature Range | Common Length Variance |

|---|---|---|---|

| Sedans | 1,800 psi | -40°C to 120°C | ±0.5" OEM spec |

| Motorcycles | 3,200 psi | -50°C to 150°C | ±0.25" critical |

| Trailers | 2,400 psi | -30°C to 90°C | ±1" maximum |

Installation, Testing, and Long-Term Reliability of Brake Hoses

Correct Length, Fittings, and Mounting Brackets for Secure Installation

Getting the right hose length is actually pretty important because otherwise they just get in the way of how the suspension moves around and bump into all sorts of parts on the chassis. Most shops these days still stick with factory style mounting brackets that come with those little torque indicator marks. These really do make a difference when putting things together since they stop the hoses from getting twisted up which nobody wants. A big headache comes from mixing different measurement systems though. We've seen plenty of cases where someone grabs a metric fitting only to find out later it doesn't match their imperial system setup. This mismatch causes problems for the seals and can drop hydraulic pressure somewhere around 30% in some situations. For anyone working on this stuff, grabbing a good quality flare nut wrench and making sure everything gets tightened down properly within that standard range of about 15 to 25 Newton meters helps keep those fittings round instead of squashed out of shape.

Common Installation Errors Leading to Premature Failure

Improper routing causes 42% of early hose failures (NHTSA 2022), particularly near sharp edges or heat sources. Over-tightening damages internal reinforcement layers, while under-torquing risks leaks. A recent study found that 68% of DIY installations exceeded the SAE-recommended twist limit of 15 degrees, accelerating wear at connection points.

Testing Procedures: Cold Bend, Ozone Resistance, and Environmental Durability

Post-installation verification includes three key tests:

| Test | Standard | Pass Criteria |

|---|---|---|

| Cold Bend (-40°C) | SAE J1401 Annex B | No cracks after 24h flex cycles |

| Ozone Resistance | ASTM D518 | 10% surface degradation at 50pphm |

| Burst Pressure | FMVSS 106 | 4,000 psi (hydraulic systems) |

Hoses validated through these protocols maintain 0.25% volumetric expansion under 1,500 psi loads, ensuring consistent pedal feel.

Long-Term Reliability Under Temperature Extremes and Vibration Stress

EPDM rubber of good quality works well across a wide range of temperatures, staying flexible even at -40 degrees Celsius and not getting brittle until it reaches around 120 degrees. For situations where there might be sudden heat increases, PTFE lined stainless steel hoses can handle short bursts of temperature up to about 260 degrees Celsius before they start to fail. When talking about vibration resistance which is really crucial for motorcycle applications, manufacturers need to make sure their hoses have braided sheathing that meets or exceeds 50 kilonewtons in tensile strength. According to field tests, if these hoses are installed correctly and kept away from direct sunlight and chemicals that eat into materials, most will maintain approximately 95 percent of their initial burst strength after being used for roughly 100 thousand miles on average.

FAQ

What are brake hoses and what role do they play in vehicle safety?

Brake hoses carry hydraulic pressure from the master cylinder to the brake calipers, enabling the brake pads to create friction with the rotors, which is essential for stopping the vehicle. Damaged hoses can significantly reduce braking power, increasing stopping distances and compromising safety.

What's the difference between rubber and braided stainless steel brake hoses?

Rubber brake hoses are common in everyday vehicles and are cost-effective, but degrade faster under harsh conditions. Braided stainless steel hoses offer better performance, tensile strength, and longevity, making them preferred for high-performance or off-road vehicles.

How do I ensure I am using the right brake hose for my vehicle?

Consult your vehicle's factory specifications for proper hose length, material, and compliance with standards like SAE J1401. Ensure compatibility with your vehicle’s make, model, and ABS requirements, especially if upgrades are involved.

Table of Contents

- Understanding the Role of Brake Hoses in Vehicle Safety

- Rubber vs. Braided Stainless Steel Brake Hoses: Performance and Use Cases

- Key Specifications for Selecting the Right Brake Hose

- Vehicle-Specific Compatibility: Matching Make, Model, and ABS Requirements

- Installation, Testing, and Long-Term Reliability of Brake Hoses

- FAQ